Companies have several options to detect and respond to a pipeline release

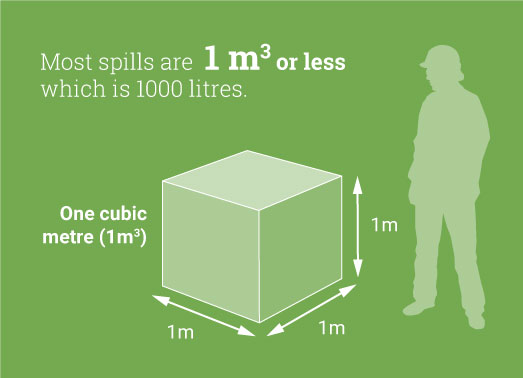

Alberta - July 02, 2019Most pipeline leaks that occur in Alberta are small. In fact, the Alberta Energy Regulator's (AER's) recently released Pipeline Performance Report shows that in 2018, over two-thirds of pipeline incidents released one cubic metre or less of fluid.

Lawrence Newby, a field inspector with the AER’s Wainwright office, believes leaks are smaller because many companies are now focusing on leak detection.

"Leak detection is not always a flashy story, but companies have made it a priority," he says. "We're seeing many leaks being detected and responded to earlier, which minimizes incident consequence."

Leak Detection 101

The AER works with industry to reduce pipeline incidents, and to ensure that companies are able to detect and respond to leaks quickly. Companies may use a variety of leak detection methods because each pipeline is different.

Here are five examples of leak detection methods used in Alberta.

- On the ground and in the air: Company inspectors travel the length of pipelines by foot, all-terrain vehicles, truck, drone, and sometimes by helicopter or plane. On the ground, company inspectors carefully scan for pipeline leaks. In the air, cameras are used. Some cameras use thermal imaging to detect leaking gas, which resembles smoke billowing up from the pipe as the temperature changes in the air above it.

- Listen carefully: Acoustic devices travel with the flowing product in a pipeline to collect data on the acoustic signature (sound) of the pipeline, which may identify a leak and its location.

- What goes in the pipe must come out: The mass, pressure, and flow of the substance in a pipe is measured at various intervals of the pipeline. Changes in the mass, pressure, or flow from previous intervals, may indicate a leak.

- Test, test, test: If a company thinks there may be a pipeline leak, a good way to test might be to close the pipeline valves and pause regular operations. Operators then monitor the pressure in the pipe to determine if leaks have occurred.

- The speed of light: Fibre-optic cables installed along the length of a pipeline can detect changes in sound, strain, vibration, and temperature. Data relayed from the cables can indicate if there is a leak.

Newby says that many companies understand the importance of having the right tools "in their toolbox," and use several methods to detect leaks. The AER supports leak detection programs by evaluating whether a company’s plan is sufficient and will protect the public and the environment from harm.

"We're looking to understand the system, evaluate whether that system works, and determine if the company is trained to execute on it."

External News Coverage

4 charts showing Alberta’s pipeline performance in 2018

JWN | June 27, 2019

Connor Doane, Writer